Design the shape for holding in your hand, like a pen. When you solder the pins to a PCB, you just route the signals to w/e connector you want, to fit to your PICKIT3 or w/e. And of course a bunch of fragile fly wires soldered onto the ends. Or some sad looking hotglue/epoxy blob to hold the pins. And all I ever see regarding DIY interface is using CNC machined/drilled blocks with the pins stuck in, even for simple SIL footprints. This is very desirable for dev or for large hex with long programming times.

The thru hole has the advantage that if you stagger the holes, you can stick a pin header in there, and it stays by itself. If you were to use 0.1", you don't really gain much over using plated thru holes for your ICSP (at least for a 2 sided board). By selecting the right thickness PCB you are close enough to perfection. Use the datasheet to find the OD of the pogo pin base you are going to order, and add that to the thickness of the PCB for the spacing. You can even do DIL, if you want, using a double-sided PCB. So you can easily replace worn/broken pins. The base is sold separately it is a hollow sheath that the entire pin slides in/out, and this base is all you solder to the PCB. The shape of the soldermask can aid in keeping the pins parallel and in alignment, if you make it narrow enough. Just edit your soldermask layer so you don't get soldermask under the middle of the pin. If you use two pads per pin with large empty space in the middle, you can much more easily get the pin straight/parallel before soldering the next one in place by walking one end at a time. Make PCB, then solder the base of the pins flat against the pcb, sideways.

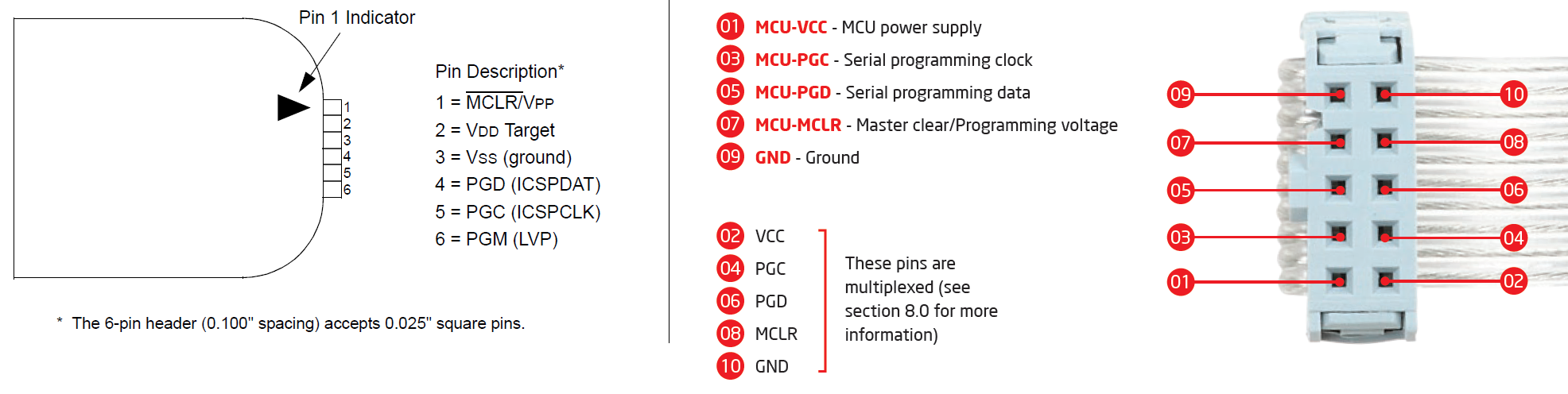

There's no need for any fancy machining equipment. Or you just populate the male header on pcb, make up a male-female connector, clearly mark all pin 1's, glue the cable on the pickit side so it doesn't 'disappear', and be done You can also have an unpopulated/staggered 5/6pin header on the pcb, but then you are stuck using a cable with a 'live' male end and still have a 'polarity' problem. The inline header is nice because you can easily come up with a way to connect (bare wires if needed), but it is not so great when needing to connect to a number of devices frequently. Maybe I'll have to make a little adapter for my pickit3 to convert to the same thing, as I dislike the non-keyed aspect as its too easy to get wrong- its like trying to plug in a usb device into a pc- it takes about 3 attempts before its right (at least with the usb you can't screw it up, you just attempt to do so a number of time). Using an swd type connector would be the same but smaller, and maybe the prices of these things (and cables) are more normal by now (haven't checked). It also can act as a normal 5 pin header if needed with a 5pin cable or jumpers (although I have male on both ends, so is opposite of normal pickit/snap). It is quite nice to have a keyed connector. I tied the lines A0, A1 and A2 high you can do anything you want, as long as you match it in the programmer software.For my Snap adapter, I use a 10 pin keyed idc- Not exactly the greatest connector for the mcu side, as its relatively large, but they are easy to get, easy to make cables for (or get pre-made cables which are also cheap and easy to find and you may already have some). The ZIF socket that came with my PICkit3 did not support the 24LC64 foot print. And then, the real work can begin… Build your programmer Then, in the programmer, switch the PICkit from MPLAB mode to programmer mode. Newest firmware I could find is included with the programmer, version PK3OSV020005.hex.

Pickit 3 pinout program upgrade#

Usually, you have to upgrade the firmware of your PICkit to something newer using Tools -> Download PICkit operating system. For instance, you can’t exit the program – it crashes! Also, when you unplug and replug your PICkit whilst the program is running, it’s no longer guaranteed to work. It’s not easy to find as it’s not officially supported.

Pickit 3 pinout program software#

Then again, it’s not exactly the truth either.įirst of all, you have to use a piece of software they don’t include – the PICkit3 programmer v3.10.

Pickit 3 pinout program full#

You see, the Microchip PICkit3 seems like a steal – a cheap, full featured PIC programmer that can also write EEPROMs! Since it took me about 8 hours to fetch all the information together and get it running, maybe this post will be useful for other loonies like me who think this is a good idea 🙂

0 kommentar(er)

0 kommentar(er)